For proven abrasion and cut resistance in the roughest conditions, insist on Dyneema® SK78 fiber inside.

Salvage and towage operations are challenging enough without having to worry about your ropes’ abrasion, cut, and tear resistance. No wonder tug operators prefer towing and salvage lines made with Dyneema® SK78 fiber.

After all, ropes made with Dyneema® – the world’s strongest fiber™ – aren’t just 15 times stronger than steel wire rope weight for weight. Dyneema® SK78 fiber is specifically engineered to overcome the weaknesses of generic HMPE alternatives. That’s why it delivers unmatched safety, reliability, and durability, even for the world’s largest vessels and in the most extreme sea conditions.

Dyneema® SK78 fiber enables longer-lasting reliability in towage and salvage ropes

Dyneema® enables STRENGTHplus+

In towing, success starts with strength – but tug operators need to be able to count on time- and cost-efficient salvage operations, too. That’s where Dyneema® comes in. As well as boasting the highest strength-to-weight ratio of any rope material, Dyneema® is molecularly engineered to withstand fatigue, abrasion, cuts, and extreme conditions, so lines can be used safely for longer.

* Compared to generic HMPE

Choosing your next mooring rope? Know your FACTs

Fatigue. Abrasion. Cut Resistance. Temperature.

Get the FACTs hereImproving safety and reliability in salvage

Even among the numerous competing priorities in today’s towing industry, safety and reliability are non-negotiable. To protect tugs and their crews during difficult and dangerous salvage and towage assignments, operators trust Dyneema® SK78 fiber – and with 25-years of trusted performance behind it, it's no wonder.

At Dyneema®, we pride ourselves on being the world’s only fiber manufacturer to test and predict rope performance as well as fiber performance. In turn, we can reduce the risk of rope failure and ensure lines can be relied on to perform safely for longer. And that’s not all: not only are we recognized by the OCIMF for our industry-leading expertise in fiber technology, rope design, and mooring practices, but we also helped develop the industry’s MEG4 and SOLAS safety standards.

For safety that lasts

Reduced chance of rope failure

Reliability from day one

Longer safe service life

Predictable longevity

Performance-driven retirement criteria

Fewer injuries

Rigorous fiber-and rope-level testing

Training on fiber types and inspections

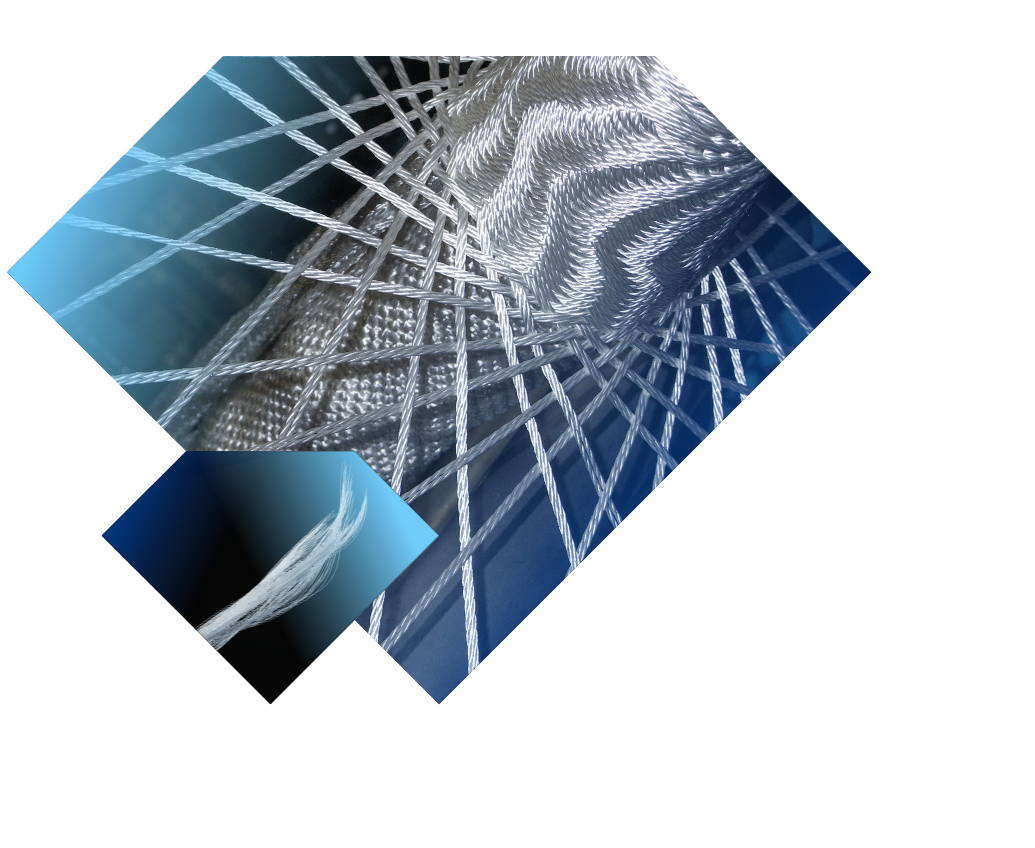

Overcoming the challenge of abrasion and cuts

Abrasion and cuts from rough and rusty hardware are some of the biggest challenges facing towage and salvage lines. Ideally, ropes must be able to withstand wear and tear from damaged fairleads, bollards, sheaves, and other surfaces – but this isn’t always the case. In fact, some ropes are made of materials that can cause damage to vessels’ equipment. With Dyneema®, it’s different.

With a proven track record in exceptional abrasion, cut and tear resistance, Dyneema® SK78 fiber outperforms generic HMPE in salvage and towage lines, ensuring maximum performance and durability. Plus, our UHMWPE doesn’t cause costly damage to other equipment. Whether you’re looking for ropes or protective covers, it's time to make tug solutions containing Dyneema® your trusted companion in the roughest conditions.

For ulitmate abrasion and cut resistance

Up to 3x longer resistance to external abrasion*

10x increase in cut-resistance cycles to failure*

Available as rope core material and as a protective jacket

Superior performance in wet and dry conditions

Enabling optimal efficiency

In high-pressure salvage situations, there’s no time to waste – which means crews need lightweight ropes that make handling easier and safer. What’s more, with operational pressures also rising, tug operators rely on weight savings as a key component in more time- and cost-efficient solutions.

Enter Dyneema® SK78 fiber: the key ingredient in synthetic lines that are seven times lighter than steel wire rope at the same strength. In fact, our fiber is so light, it floats on water without absorbing any moisture – keeping personnel safer, making operations easier and faster, and reducing costs, all at once.

For lightweight ropes with heavyweight performance

Higher productivity

Fewer tugs and crew members required

Lower operational costs

Safer handling

Supporting a more sustainable industry

Tugs and salvage play a crucial role in protecting maritime operations, but they increasingly need to contribute to protecting our planet, too. With the sustainability transition well underway, every fiber in every towage rope counts. And Dyneema® fiber counts more than others.

That’s because 100% of the electricity we use to make the world’s strongest fiber™ comes from renewable sources. And because the properties and performance of ropes with Dyneema® inside enable downstream energy efficiencies. All in all, choosing Dyneema® SK78 fiber means choosing a lower carbon footprint for your tow and salvage solutions – helping put you at the crest of the sustainability wave.

For a big impact with a small footprint

Less material use thanks to a longer service life

Less energy use with fewer salvage tugs needed

Lower carbon footprint than ropes made with generic HMPE

Dyneema® fiber from bio-circular feedstock available

Want the same high performance with a lower carbon footprint?

Discover Dyneema® fiber from sustainable raw materialsPutting fiber and rope performance to the test

Testing fiber breaking strength is one thing. Knowing how a tow rope will perform in real-world conditions is another. We not only manipulate Dyneema® SK78 fiber at the molecular level to be more than a match for the most challenging salvage operations, but we also test it rigorously at both fiber and rope level.

In fact, Dyneema® is the only fiber manufacturer to evaluate product performance by simulating realistic conditions. We’re so committed to ensuring – and even predicting – our fiber’s performance in maritime lines, we’ve built a proprietary suite of state-of-the-art testing equipment.

MEG4 and Dyneema® SK78 fiber: Setting the Standard

Our specialists have a long track record of collaborating with the OCIMF on its Mooring Equipment Guidelines (MEG) and more. Today’s industry standard, MEG4, adopts a holistic view of a rope’s lifetime performance – an approach we support.

Contact our sales team

Whether you’re an engineer or a buyer, selecting the right ropes for towage and salvage tugs is a big decision. With Dyneema®, you can consider our experts part of your crew. We’re always on hand to help you find a safe, reliable, durable, and cost-effective solution.

- Expert understanding of salvage and tow operations

- Unrivaled knowledge of rope performance for optimal safety and efficiency

- Support with material selection

- Training on different fiber types

- Advice on regulatory compliance

- Guidance on the questions you should be asking your rope supplier

Read our case studies

Preferred. Trusted. Certified

Dyneema® SK78 fiber is renowned the world over for its outstanding quality, consistency, and performance – as recognized by our array of third-party certifications. Contact us to find out more.

DNV GL approval of fiber manufacturing

DNV GL technology qualification: Creep Performance Tool

Bureau Veritas type approval for mooring rope fibers

ClassNK certification

Keep in mind that the maritime supply chain is vulnerable to fake mooring certificates. You should always authenticate third-party certificates to prevent rogue suppliers from putting your crew at risk.

Stronger together

Our premium partners are dedicated to manufacturing strong, safe, and reliable salvage and towing lines using Dyneema® SK78 fiber – all made in accordance with MEG4, of course. Looking for extra peace of mind? Our partners are happy to offer the service and maintenance packages you need to keep your operations running smoothly and safely, day in, day out.

Where to buy

Towage and salvage ropes made with Dyneema® SK78 fiber are available from our trusted sellers across the globe.

Find a providerDesign with Dyneema®

If you design towing and salvage systems, our team would love to work with you. We’ll put all our experience into helping you develop your ideal performance solutions, using our exceptional Dyneema® SK78 fiber.

Our technical centers across the globe are always looking to the horizon, so we can anticipate the next big thing in the industry. Our experts engineer for the future, so we can keep delivering the next generation of innovation. And our teams can help you certify your system, so you can keep your operations moving no matter where in the world you are.