Fabric Finder Guide

We use the world’s strongest fiber™ to make ultralight, super strong, and fully waterproof composite materials. In turn, these composites are used by product designers to craft a wide range of high-performance sports and consumer goods.

Our Dyneema® Fabric Finder contains technical information about every composite material made with the world’s strongest fiber™ – engineered for outstanding performance in extreme conditions.

What is Dyneema®

Dyneema® is the world’s strongest fiber™.

More specifically, it’s a premium brand of ultra-high-molecular-weight polyethylene (UHMWPE). Dyneema® is 15 times stronger than steel, yet light enough to float on water. This unbeatable strength-to-weight ratio is used in our fabrics to minimize weight and maximize durability – enabling products that keep elite adventurers light on their feet.

With over 30 years of material science expertise and experience, Dyneema® continues to lead the industry in fiber innovation, delivering unmatched strength, durability, and reliability in a range of composite grades.

About Dyneema® composites

All of our Dyneema® composites are constructed using Dyneema® fibers, which are bonded into a perpendicular, cross-ply structure. We call this a Dyneema® core. This core construction provides our composites with exceptional strength, dimensional stability, and resistance to tearing.

Additional face fabrics and film layers are then added to this Dyneema® core to provide extra mechanical and physical properties. So, whether your application requires pressure retention, optimized adhesion, or enhanced waterproof protection, Dyneema® composites can be engineered to enable precise performance attributes.

Looking for our military or inflatable-grade materials? Get in touch with us directly.

For knits, wovens, and denims with Dyneema®, explore more here:

Engineered for a wide range of end-use applications

Designers and product development specialists choose Dyneema® when they need a low-weight, high-tensile strength, and high-modulus material for the most demanding applications and end products on the market.

The world’s strongest fiber™ has already been used to empower products at the very pinnacle of elite sport, including sailing equipment used during the America’s Cup and cycling gear at the Tour de France.

Contact our sales team

Maecenas faucibus mollis interdum. Aenean lacinia bibendum nulla sed consectetur. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Etiam porta sem malesuada magna mollis euismod.

Get in touchDimensional Stability:

The bedrock of every Dyneema® composite

The core of every Dyneema® composite is a unique structure engineered for unmatched dimensional stability. To construct this core, Dyneema® fibers are layered and bonded at 0° and 90°, creating a structure that doesn’t sag or stretch. When combined with woven face fabrics – which themselves tend to stretch easily – the Dyneema® core effectively locks these other layers in place, preventing unwanted deformation and enhancing structural stability and durability.

Our Dyneema® composites can also be precisely tailored for strength, elasticity, weight, and thickness, making them highly adaptable to a wide range of performance needs. And, because these composites are built from high-modulus fibers, they exhibit predictable, linear properties that are ideal for high-stakes product designs where reliability is critical.

Fabric Construction Guides

Every Dyneema® composite is engineered with the same ultra-strong base layer: a Dyneema® core made from the world’s strongest fiber™.

But what’s added to that Dyneema® core helps to define its unique properties, performance attributes, and appearance. The final composite material will be one of our specialized product grades.

Explore our dedicated fabric construction pages for more information about the structure and composition of our different high-performance composites.

Finding the Optimal Strength-to-Weight Ratio

Unlike conventional fabrics, Dyneema® composites are engineered to strike the ideal balance between strength and weight. But since this can differ depending on the application, Dyneema® composites are available in a range of linear densities.

With fabric weights in this guide ranging from 0.55 oz/yd² to 5.9 oz/yd² (19 gsm to 200 gsm), Dyneema® allows for precise customization – delivering the ideal performance properties needed at the required weight.

If you require a composite material with a specific strength or weight not listed in this guide, contact our experts.

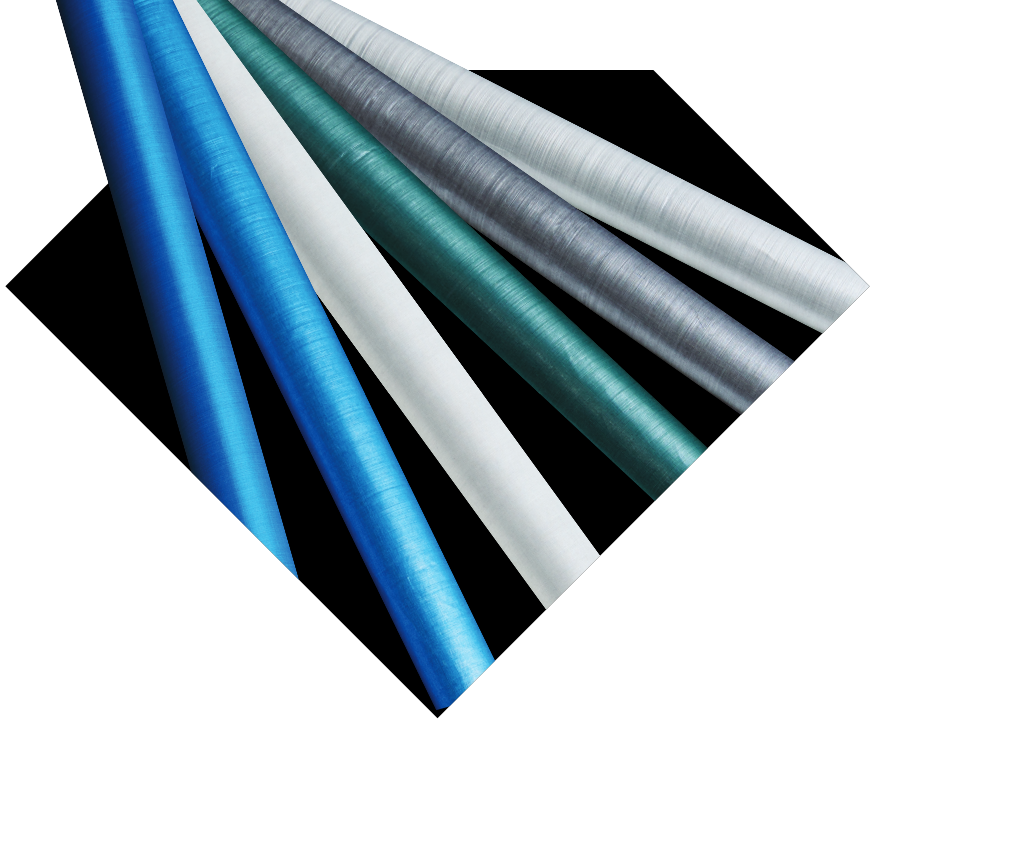

Get in touchA range of available colours to choose from

Dyneema® composites are available in a variety of colors to suit different applications, styles, and environments. From classic tones like blue, black, and white to stealthy olive drab or rugged multi-camouflage, every shade provides the same trademark performance properties of the world’s strongest fiber™.

Select a fabric grade to explore available colors or contact us for more details.

Proven performance through rigorous testing.

Every Dyneema® composite undergoes extensive laboratory testing by our technical experts – to validate its performance characteristics and reliability for end-use applications.

Our global in-house laboratories conduct:

- Tensile testing

- Tear testing

- Puncture testing

- Peel strength testing

- Taber abrasion testing

- Hydrostatic head testing

- Precision microscopy

Beyond the lab

We also partner with our customers to perform real-world field testing. That way, we’re certain that our materials perform reliably in demanding environments.

Independent third-party testing provides further validation, ensuring Dyneema® consistently delivers top-class performance in a range of end products.

Key Performance Benefits

Dyneema® is the world’s strongest fiber™ – and not by accident. Every composite we produce is molecularly engineered and meticulously designed to meet the unique demands of end-use applications.

Here are the key attributes that make Dyneema® the leading choice for high-performance gear:

All Our Composites Are Made With Bio-Circular Dyneema® Fiber

All Dyneema® composites are made with bio-circular Dyneema® fiber – the world’s first-ever bio-circular HMPE fiber.

Bio-circular Dyneema® fiber is produced using a mass balance accounting approach. By-products from the pulp and timber industries are collected as renewable feedstock, which is combined with fossil-based feedstock and processed to create ethylene – the key ingredient in Dyneema® fibers. The renewable share is then allocated as bio-circular Dyneema® fiber.

All production steps use our existing infrastructure and processes – so apart from a smaller carbon footprint, there is absolutely no change in material construction or product performance.

No intentionally added PFAS chemicals

The unique properties of Dyneema® composites mean they can achieve desirable levels of water resistance without needing PFAS-based surface treatments.

Ordering small quantities

Need to buy a small quantity of a Dyneema® composite material?

If your order doesn’t meet our minimum quantity requirements, don’t worry. We have trusted distributors who can fulfil your order.

Ripstop by the Roll (US)

Dutchware (US)

Takisada Nagoya (Japan)

extremtextil (Germany)

Ripstop.pl (Poland)

Hwasung (Korea)

Gayon (China)

Ordering samples

Want to try before you buy? No problem. Get in touch with our Dyneema® experts to discuss sampling our high-performance composites.

Explore more